Installation method of polytetrafluoroethylene Glide-ring /Stepseal

2023-07-19

Installation method of polytetrafluoroethylene Glide-ring/Stepseal

一、Pre installation processing

Check the surface quality of the sealing element and ensure that there are no defects such as flash, burrs, cracks, trimmings,air holes, and looseness.The geometry and accuracy of the seals should meet the standard requirements.The wear-resistant ring is mainly made of filled polytetrafluoroethylene (PTFE) material, which has corrosion resistance characteristics and a large coefficient of thermal expansion. Therefore, before installation, soak it in 100 ℃ oil for 20 minutes to gradually soften it, and then use tooling to install it into the groove of the piston.Attention: Due to the post shrinkage property of polytetrafluoroethylene stored for a long time, it is normal for the size to be reduced. It can be avoided by installing after softening, or it can be appropriately stretched and installed without affecting its use.

二、 Installation of stepped combination sealing ring

2.1 Installation method tips for installing composite seals (Stepseal,Glide-ring) in the overall groove of the piston:When installing combination sealing rings such as the Steckel seal and Glay ring, it is necessary to pay attention to the PTFE slip ring and rubber sealing ring. After installing them into the overall groove, the PTFE slip ring must be calibrated.

(1) Please prepare the bushing and push rod tools as shown in Figure 1. Before assembly, please rinse the inner surface of the hydraulic cylinder chamber and the surface of the assembly groove clean.

Figure 1 Stepseal/Glide-ring groove cleaning tool

(2) Please install the rubber ring into the assembly groove. At this point, please avoid excessive stretching and twisting of the rubber sealing ring, as shown in Figure 2.

Figure 2 O-ring for Installation Hole

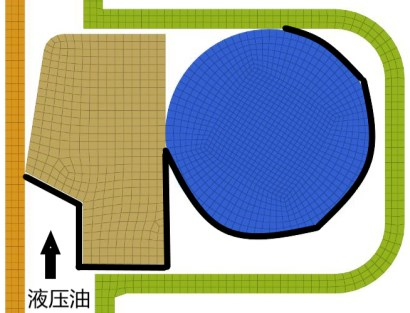

(3)Install the bushing into the piston, and then use a push rod tool to quickly press in the slip ring, as shown in Figure 3.

Figure 3 Pushing the Stepseal/Glide-ring into the groove

2.2 Installation of piston rod Stepseal/Glide-ring.

(1) First, place the O-ring in the groove.

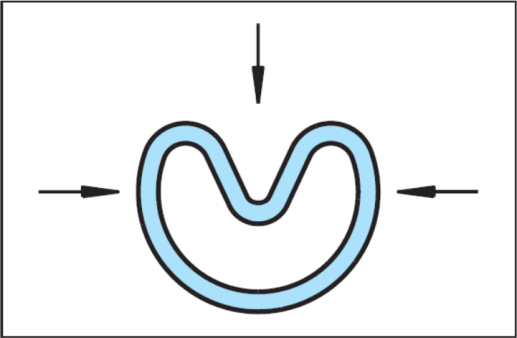

(2)Bend the Stepseal into a waist shape, as shown in Figure 1. The seal must not be bent (Figure 4).

Figure 4 Seal Ring Bending and Deformation

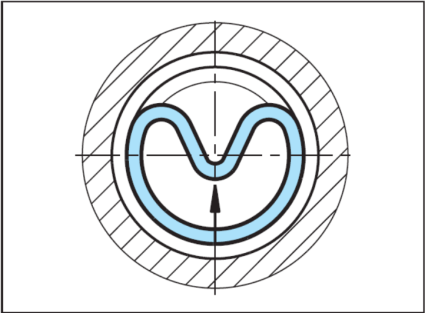

(3)Put the bent sealing ring into the groove and push it to the O-ring in the direction of the arrow (see Figure 5).

Figure 5 Put the sealing ring into the sealing groove (only Stepseal ,Glide-ring is symmetrical, regardless of the direction).

(4)After being put into the groove, it is best to roll the seal flat with your fingers so that it forms a circle and abuts against the groove.

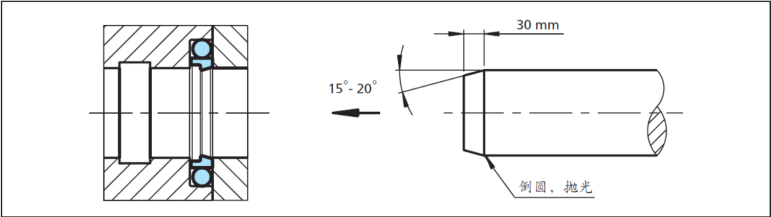

(5)Finally, the sealing ring is leveled with a mandrel with a length of about 30 mm and an angle of 10 to 15.In order to avoid damaging the seal, the leveling mandrel should be made of polymer material with good sliding characteristics and surface quality (such as Nylon).When using a piston rod with a long guide post, it also has a leveling function.

Figure 6 Leveling of installed seal

Please contact Guangdong DEF SealS if you want to know more about the installation methods of Stepseal,Glide-ring, piston rod seal and piston seal ring.

News